Infrastructure

We ensure that every product we deliver meets the highest industry standards

MANUFACTURING FACILITY

We are located in Silicon Valley of Bangalore, India with fully equipped automatic SMT & PTH Line with 6100 Sqft of work space.

MANUFACTURING EQUIPMENTS

1. ETA FULLY AUTOMATIC SCREEN PRINTER

| Model | E-Star |

| Frame Size(mm) | 370*370 ~ 737*737 |

| Thickness | 25~40mm |

| PCB Size(mm) | 50*50 ~ 400*340 |

| PCB Thickness | 0.4~6mm |

| PCB Warpage | <1% |

| Transport Height | 900±20mm |

| Transport Direction | Left-Right; Right-Left; Left-Left; Right-Right |

| Transport Speed | Max 1500mm/s |

| Support System | Magnetic Pin/Up-down table adjusted/support block |

| Clamping System | Side clamping, vacuum nozzle, Automation retractable Z pressure |

| Printer Head | Two independent motorised printhead |

| Squeegee Speed | 6~200mm/sec |

| Squeegee Pressure | 0~15kg |

| Squeegee Angle | 60°/55°/45° |

| Squeegee Type | Stainless steel(standard), Plastic |

| Release Speed | 0.1~20mm/sec |

| Cleaning System | Dry, Wet, Vacuum |

| Table Adjustment Ranges | X:±10mm;Y:±10mm;θ:±2° |

| Table Adjustment control | Motor |

| Mark Types | Circle,Triangle,Square,Diamond,Cross |

| Mark Size | 0.5~3.0mm |

| CCD FOV | 10*8mm |

| Vision Methodology | CCD, Top and Bottom |

| Inspection | 2D Inspection (Standard) |

| Repeat Accuracy | ±0.01mm(CPK ≥ 2.0) |

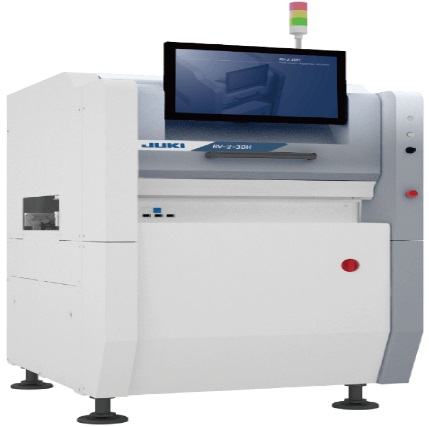

2. JUKI 3D BOARD VISUAL INSPECTION MACHINE (RV – 2 – 3DH)

| Board size | 50mm×50mm-410mm×300mm 50mm×50mm-630mm×300mm (action to long board)*1 |

| Test resolution | 12μm (standard resolution)/5μm (high resolution)*1 |

| Image angle | 48.0×36.0mm、20.0×15.0mm*1 |

| Inspection items | Shorting, shear, polarity, side-reverse, unsoldered solder, bridge, solder quantity, insertion part omission, character recognition*1 |

| FOV (Optimum condition) 2D | 0.2sec/1 screen |

| FOV (Optimum condition) 3D | 61.8cm²/sec |

3. JUKI FAST SMART MODULAR MOUNTER (RS – 1R) - 1

Fast Smart Modular Mounter

| Model |

|

|||

| Conveyor specification |

|

|||

| Board size – Minimum |

|

|||

| Board size – Maximum – 1 buffer |

|

|||

| Board size – Maximum – 3 buffers |

|

|||

| Component Height |

|

|||

| Component Size |

|

|||

| Placement speed |

|

|||

| Placement accuracy |

|

|||

| Vision recognition |

|

|||

| Feeder inputs |

|

4. JUKI FAST SMART MODULAR MOUNTER (RS – 1R) - 2

Fast Smart Modular Mounter

| Model |

|

|||

| Conveyor specification |

|

|||

| Board size – Minimum |

|

|||

| Board size – Maximum – 1 buffer |

|

|||

| Board size – Maximum – 3 buffers |

|

|||

| Component Height |

|

|||

| Component Size |

|

|||

| Placement speed |

|

|||

| Placement accuracy |

|

|||

| Vision recognition |

|

|||

| Feeder inputs |

|

5. ETA T-T SERIES LEAD FREE REFLOW OVEN

| ETA Reflow Oven Specifications |

|

|

| Specifications |

|

|

| Machine Dimension (L*W*H)mm |

|

|

| Package Dimension (L*W*H)mm |

|

|

| Weight |

|

|

| Board Dropped Alarm |

|

|

| Standard Colour |

|

|

| Electrical SMEMA Interface |

|

|

| Number Of Heating Zones |

|

|

| Length Of Heating Zones |

|

|

| Computer |

|

|

| Max.Width Of PCB |

|

|

| Rail Width |

|

6. FULLY AUTOMATIC BGA PLACEMENT & REWORK STATION

| For high volume BGA Rework on even the largest computer and networking boards! |

| This BGA Rework System has High-Definition, Auto-X-Y and Theta Split-Vision Alignment for Automatic Removal, Placement, and Soldering of BGAs, CGA’s, CSPs, QFPs, LGA’s and Other SMDs. The rapid-IR underheated is a must for large PCB’s with many layers or heavy ground planes. |

| Auto soldering and mounting function. |

| Standard fits Boards to 24″, Optional upgrade to 36″ |

| Places components 4mm and up. Optional 1mm upgrade available. |

| 1200 watt component heater (Top Side) |

| 800 watt component heater (Bottom Side) |

| 6-zone 3600 Watt rapid-IR under heater |

| Powerful cross flow fans cool the bottom heating area rapidly with stable speed. |

| Color optical system with functions of split vision, zoom in/out and micro-adjust. |

| Auto focus and software operation function, 2 million pixel high-definition camera. |

| 15’’ high-definition LCD monitor. |

| Five Thermal Couple Inputs. |

| Fully self contained with PLC control. No need for external air. |

7. FULLY AUTOMATIC BGA PLACEMENT & REWORK STATION

| Item |

|

||||||||||||

| Panel Detector |

|

||||||||||||

| Microfocus |

|

||||||||||||

| X-ray source |

|

||||||||||||

| Sample Table |

|

||||||||||||

| Software Function |

|

||||||||||||

| Power |

|

||||||||||||

| Computer |

|

||||||||||||

| Radiation Standard |

|

||||||||||||

| Machine Shell |

|

||||||||||||

| Other functions |

|